Welcome to todays post all about choosing the right fibreglass repair products for boat repairs.

Ever wondered why fibreglass repair is such a big deal for boat owners? Well, let me tell you straight up: it’s the backbone of keeping your vessel sailing smoothly.

Your boat’s hull takes a beating from the waves, rocks, and whatever else the sea throws its way. Cracks, chips, and splits are inevitable, but here’s the kicker—ignoring them can lead to a world of trouble, from water seeping in to compromising the structural integrity of your prized possession.

But hey, don’t sweat it just yet. The market’s flooded with fibreglass repair products, each claiming to be the Holy Grail of boat maintenance. From fibreglass cloth to resin to fillers, you’ve got options coming out the wazoo.

But here’s the deal: not all products are created equal. Choosing the wrong ones can leave you with shoddy repairs that’ll have you bailing water faster than you can say “anchors away.”

So, buckle up because in this guide, I’m going to walk you through the mine field of selecting the right fibreglass repair products. We’re talking about the stuff that’ll patch up those cracks like they never even happened.

Stick with me, and I’ll make sure you’re armed with the knowledge to keep your boat afloat for years to come. Let’s dive in.

Table of Contents

Understanding Fibreglass Repair Needs

Alright, let’s get down to business. When it comes to fibreglass repair for boats, we’re talking about dealing with some pretty common headaches: cracks, punctures, and delamination. Think of them as the trifecta of trouble for boat owners.

First up, cracks. These pesky little buggers can pop up just about anywhere on your boat’s hull, deck, or even its interior. Whether it’s from rough seas or just wear and tear over time, cracks are like tiny invitations for water to sneak in and wreak havoc.

Next on the list, punctures. Picture this: you’re cruising along, minding your own business, when suddenly—bam!—you hit something lurking beneath the surface.

Before you know it, you’ve got a hole in your boat the size of a grapefruit. Punctures may not be as common as cracks, but when they happen, they’re a real pain in the hull.

Last but not least, we’ve got delamination. This sneaky little devil occurs when the layers of fibreglass start separating from each other, usually due to moisture or improper bonding during construction.

It might not seem like a big deal at first, but trust me, it’ll spread if left unchecked.

Now, here’s the kicker, before you start slapping on fibreglass repair products like there’s no tomorrow, you’ve gotta assess the damage like a pro.

I’m talking about getting up close and personal with those cracks, punctures, and delamination spots. Size ’em up, figure out how deep they go, and most importantly, understand what caused them in the first place.

Why’s this step so crucial? Because not all fibreglass repair products are created equal. Some are better suited for small cracks, while others are built to tackle larger punctures or delamination issues.

By knowing exactly what you’re up against, you’ll save yourself time, money, and a whole lot of frustration down the line.

Types of Fibreglass Repair Products

Now that you’ve sized up the damage on your boat, it’s time to talk turkey about fibreglass repair products. We’ve got a lineup of heavy hitters ready to tackle those cracks, punctures, and delamination like nobody’s business. Let’s break ’em down

Fibreglass Cloth:

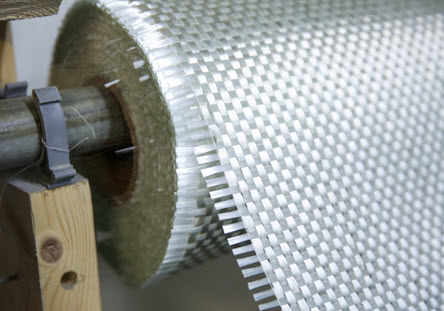

When it comes to patching up those nasty cracks and holes, fibreglass cloth is your go-to buddy. Now, there are a couple of flavors to choose from: woven and chopped strand mat (CSM).

Woven fibreglass cloth is like the sturdy workhorse of the fibreglass world. It’s made up of tightly woven strands, making it super strong and durable. This stuff’s perfect for repairing larger areas or areas that need extra reinforcement.

On the flip side, chopped strand mat is like the scrappy underdog. It’s made up of randomly chopped fibreglass strands held together with a binder. While it may not be as pretty as woven cloth, it’s great for filling in smaller cracks and crevices.

So, which one should you choose? Well, it all depends on the size and severity of the repair job. If you’re dealing with a big ol’ hole in your boat, go for the woven cloth. But if it’s just a few hairline cracks, chopped strand mat should do the trick just fine.

Resin:

Alright, let’s talk resin. This stuff is the glue that holds your fibreglass repair together, so you better believe it’s important. There are two main types to choose from: polyester and epoxy.

Polyester resin is like the budget-friendly option. It’s cheap, easy to work with, and cures relatively quickly. But here’s the catch—it’s not as strong or durable as its epoxy counterpart.

So, if you’re looking for a quick fix and don’t mind sacrificing a bit of strength, polyester resin might be the way to go.

On the other hand, epoxy resin is like the high roller of the fibreglass world. It’s stronger, more durable, and better suited for underwater repairs. Plus, it bonds like nobody’s business, making it perfect for those tough-to-reach spots.

Again, the choice comes down to the specific needs of your repair job. If you’re just patching up a small crack above the waterline, polyester resin should do the trick. But if you’re dealing with a major repair or need something that’ll hold up underwater, epoxy resin is your best bet.

Fillers:

Now, let’s talk fillers. These bad boys are like the icing on the cake, helping reinforce and shape your repairs. There are a ton of options out there, but some common ones include microballoons and colloidal silica.

Microballoons are like tiny little bubbles that add strength and buoyancy to your repair. They’re great for filling in gaps and creating a smooth surface, but they can be a bit tricky to work with.

Colloidal silica, on the other hand, is like the heavy hitter of the filler world. It’s super fine and incredibly strong, making it perfect for structural repairs. Plus, it cures rock-hard, ensuring your repair stays put for years to come.

Tools and Accessories:

Last but not least, you’re gonna need some tools and accessories to get the job done right. Think gloves, brushes, mixing pots—the whole shebang. Trust me, trying to tackle a fibreglass repair job without the right gear is like trying to build a house without a hammer. It just ain’t gonna happen.

So, before you dive headfirst into your repair project, make sure you’ve got all the essentials on hand. Your boat—and your sanity—will thank you later.

Factors to Consider When Choosing Products

When it comes to choosing fibreglass repair products for your boat, you’ve gotta think about more than just slapping on some resin and calling it a day. Here are the key factors you need to keep in mind:

Compatibility:

Listen up, folks—this is a big one. You can’t just throw any old fibreglass repair products together and expect them to play nice. Nope, you’ve gotta make sure they’re compatible with each other and with the existing fibreglass structure of your boat.

Trust me, the last thing you want is for your repair job to turn into a hot mess because you didn’t do your homework.

Strength and Durability:

You’ve gotta ask yourself: what kind of beating is my boat gonna take? If you’re cruising on calm waters and your repair job is more cosmetic than anything else, you might be able to get away with some less heavy-duty products.

But if you’re braving rough seas or your repair needs to hold up under serious stress, you’re gonna want to invest in the good stuff.

Ease of Application:

Let’s be real here—nobody wants to spend hours slaving away on a fibreglass repair job. That’s why ease of application is key. You want products that are a breeze to work with, whether you’re a seasoned pro or a DIY newbie.

And don’t forget about curing time. Some products take ages to dry, which can seriously cramp your style if you’re itching to get back out on the water.

Environmental Considerations:

Now, let’s talk about the elephant in the room: the environment. We all know that fibreglass repair products aren’t exactly Mother Nature’s best friend.

That’s why it’s important to think about the impact of certain products on marine ecosystems. Look for environmentally friendly options whenever possible, and make sure to dispose of any leftover materials properly.

Budget:

Last but not least, we’ve gotta talk about everyone’s favorite topic: money. Let’s face it—boat repairs ain’t cheap. But that doesn’t mean you have to break the bank to get the job done right.

Consider your budget carefully and weigh the cost of different products against their performance. Sometimes, a slightly pricier option is worth it in the long run if it means you won’t have to redo the repair down the line.

Tips for Successful Fibreglass Repairs

You’ve got your products lined up and your boat’s ready for some TLC. But before you dive in headfirst, take a minute to check out these crucial tips for a job well done.

Surface Preparation:

This step is non-negotiable. Proper surface preparation sets the foundation for a successful fibreglass repair job. That means cleaning the area like your life depends on it—no grease, grime, or dirt allowed.

And don’t forget to give it a good sanding to rough up the surface and give the repair products something to grip onto. Trust me, skipping this step is like building a house on quicksand—it’s just asking for trouble.

Mixing Ratios and Application Techniques:

This ain’t rocket science, folks, but it’s still important to get it right. Follow the instructions on your resin and hardener to a T—no eyeballing allowed.

And when it comes to applying the mixture, take your time and work in small batches. Smooth, even strokes are the name of the game here, folks. None of that slapdash nonsense.

Curing and Sanding:

Patience is key here, once you’ve laid down your fibreglass cloth and resin, give it plenty of time to cure—no rushing allowed. And when it’s finally dry, break out the sandpaper and get to work.

Sanding between layers is crucial for a smooth, seamless finish. Trust me, nobody wants to feel rough spots or bumps under their fingertips when they’re out on the water.

Safety Precautions:

Last but not least, let’s talk safety. I can’t stress this enough, folks—fibreglass repair products are no joke. Wear protective gear like gloves, goggles, and a respirator to keep yourself safe from harmful fumes and particles.

And work in a well-ventilated area to minimize exposure. Your health is worth more than any boat repair job, so don’t cut corners when it comes to safety.

Conclusion:

Ok, let’s wrap things up with a quick recap of what we’ve covered today:

First off, we talked about the importance of choosing the right fibreglass repair products for your boat. From cracks to punctures to delamination, we’ve seen how crucial it is to assess the damage and select products that’ll get the job done right.

We looked into the different types of fibreglass repair products available, from cloth to resin to fillers, and discussed how each plays a role in patching up those pesky boat problems.

Then, we tackled the key factors to consider when choosing products, from compatibility to strength to ease of application. It’s all about finding the right balance for your repair needs and your budget.

Next, we laid out some essential tips for successful fibreglass repairs, including proper surface preparation, mixing ratios, curing, and sanding. Trust me, folks—these steps are non-negotiable if you want to get the job done right the first time.

And finally, we wrapped things up by emphasizing the importance of choosing the right fibreglass repair products to maintain your boat’s integrity. Remember, folks—your boat is your baby, so don’t cut corners when it comes to repairs.

Now, I want to leave you with a final thought: don’t be afraid to ask for help if you need it. Assessing your repair needs carefully is crucial, and sometimes, that means seeking professional advice and I’m here for you if you need some help, you can contact me here.

There’s no shame in admitting when you’re in over your head, folks.

So, whether you’re a seasoned boat owner or a newbie just dipping your toes in the water, I encourage you to share your experiences and ask questions related to fibreglass boat repairs.

We’re all in this together, folks, and there’s plenty to learn from each other’s successes and failures.

Alright, folks, that’s a wrap. Thanks for joining me on this fibreglass repair journey, and until next time, happy sailing!

FAQ Section

Q: What is the best fiberglass resin for boat repair?

A: It depends on the specific repair needs, but epoxy resin is often preferred for its strength and durability.

Q: Is polyester or epoxy resin better for boat repair?

A: Epoxy resin is typically better for boat repair due to its superior strength, adhesion, and resistance to moisture.

Q: What are the different types of fibreglass repair?

A: Common types include patching cracks, filling holes, reinforcing weakened areas, and repairing delamination.

Q: What filler to use on fibreglass boat?

A: Fillers such as microballoons or colloidal silica are commonly used on fibreglass boats for reinforcement and shaping repairs.

Q: What is the best filler to use on fiberglass?

A: For fiberglass repairs, epoxy-based fillers tend to offer the best adhesion and durability.

Q: What is the best body filler to use on fiberglass?

A: Epoxy-based body fillers are often recommended for use on fiberglass due to their compatibility and durability.

Q: What are the disadvantages of polyester resin?

A: Polyester resin is less durable, more prone to shrinkage, and can degrade in sunlight compared to epoxy resin.

Q: What is the best resin for hull repair?

A: Epoxy resin is typically the best choice for hull repair due to its superior strength, adhesion, and resistance to moisture.

Q: Is Marine Tex an epoxy or a resin?

A: Marine Tex is an epoxy-based repair compound commonly used for marine applications, including boat repairs.